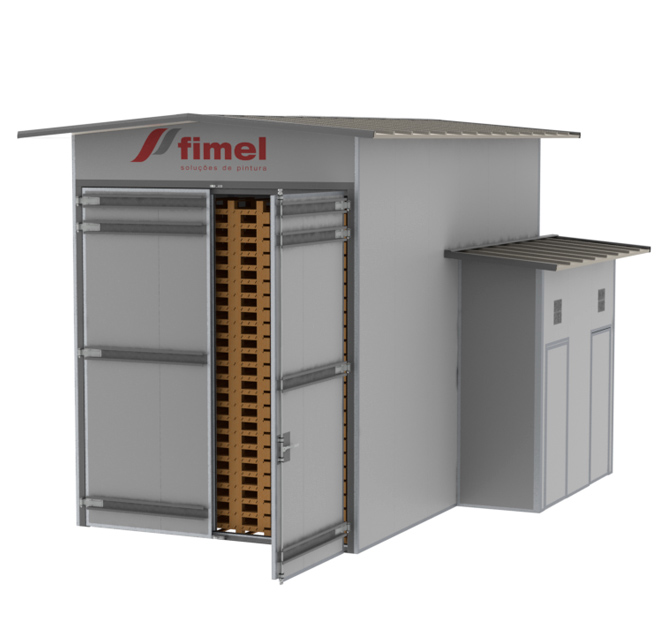

Phytosanitary Treatment Greenhouse

Phytosanitary Treatment Greenhouse

The treatment of pallets can be achieved in two ways, thermal shock or fumigation.

Fimel opted for the first, because “it is a faster process, therefore more advantageous for the customer, also because it has a much more efficient handling level, which is considered to be another important asset”.

According to ISPM 15, minimum requirements for this infrastructure are considered to be a set of equipment that enables the economic operator to carry out the phytosanitary treatment by thermal shock. For this, the presence, under operating conditions, of a treatment chamber equipped with a heat source, temperature measurement probes and sensors and an automatic system for recording parameters that are fundamental to the control of the treatment conditions that can be measured.

According to ISPM 15, the wooden package must be heated so that the center of the wood reaches a minimum temperature of 56ºC for a minimum period of 30 minutes. For this, the temperature in the center of the wood must be controlled by placing probes (thermoresistance) inserted in the center of the thicker pieces.

For the treatment to be valid it is necessary that none of the probes register, at any time, temperatures below 56ºC during a continuous period of 30 minutes.

Fimel solutions include all these premises.

Currently, the company already has five different greenhouses for the national market, it being up to the customer to choose the one that will best serve their needs. The difference between them lies, above all, in terms of capacity, the smaller ones hold around 240 pallets, the largest of which holds 1500.

DATASHEET

GREENHOUSE FOR PHYTOSANITARY TREATMENT – TYPE I

- Dimensions: 3 900 x 4 600 x 5 000 (A.L.C) mm

- Heating using an automatic diesel burner with 254 560 Kcal

- Diesel tank with 750 liters.

- With 89,7 m3

- It has 4 fans, with a 2 HP motor each and a total air flow of 48000 m3/h

- It has 10 temperature probes: 8 to control the temperature in the part and 2 to control the air temperature.

- Gas outlet duct, with reading sockets and hat.

- Greenhouse capacity: 300 to 360 pallets.

GREENHOUSE FOR PHYTOSANITARY TREATMENT – TYPE II

- Dimensions: 3 900 x 3 300 x 5 000 (A.L.C) mm

- Heating using an automatic diesel burner with 206 400 Kcal

- Diesel tank with 750 liters.

- With 64,35 m3

- It has 3 fans, with a 2 HP motor each and a total air flow of 36000 m3/h

- It has 10 temperature probes: 8 to control the temperature in the part and 2 to control the air temperature.

- Gas outlet duct, with reading sockets and hat.

- Greenhouse capacity: 200 to 240 pallets.

GREENHOUSE FOR PHYTOSANITARY TREATMENT – TYPE III

- Dimensions: 3 700 x 2 600 x 4 000 (A.L.C)´mm

- Heating using an automatic diesel burner with 103 200 Kcal

- Diesel tank with 750 liters.

- With 38,48 m3

- It has 2 fans, with a 2 HP motor each and a total air flow of 24000 m3/h

- It has 10 temperature probes: 8 to control the temperature in the part and 2 to control the air temperature.

- Gas outlet duct, with reading sockets and hat.

- Greenhouse capacity: 120 to 174 pallets.

GREENHOUSE FOR PHYTOSANITARY TREATMENT – TYPE IV

- Dimensions: 3 900 x 5 000 x 6 000 (A.L.C)mm

- Heating using an automatic diesel burner with 254 560 Kcal

- Diesel tank with 750 liters.

- With 117 m3

- It has 4 fans, with a 2 HP motor each and a total air flow of 48000m3/h

- It has 10 temperature probes: 8 to control the temperature in the part and 2 to control the air temperature.

- Gas outlet duct, with reading sockets and hat.

- Greenhouse capacity: 400 to 450 pallets.

GREENHOUSE FOR PHYTOSANITARY TREATMENT – TYPE V

- Dimensions: 4 000 x 6 600 x 4 500 (A.L.C)mm

- Heating using an automatic diesel burner with 254 560 Kcal

- Diesel tank with 750 liters.

- With 118,8 m3

- It has 4 fans, with a 2 HP motor each and a total air flow of 48000m3/h

- It has 10 temperature probes: 8 to control the temperature in the part and 2 to control the air temperature.

- Gas outlet duct, with reading sockets and hat.

- Greenhouse capacity: 750 to 800 pallets.